Casing-Wear-and-Stiff-String-Modeling-Sensitivity-Analysis PDF 1

0 likes | 8 Views

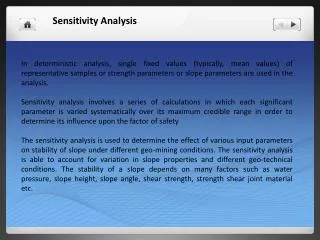

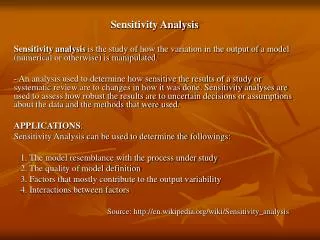

Casing wear due to pipe body and tool-joint of Range 2 and Range 3 DP is compared using a stiff-string torque & drag & buckling model coupled to a 3D<br>meshed casing wear calculation. Results are compared for multiple well profiles, either smooth or tortuous, in addition to differing pipe-body and tool-joint<br>wear factors.<br>The driving force behind the study was to investigate if the benefits Range 3 DP over Range 2 DP, such as reducing the ECD during drilling as well<br>increasing the lifespan of rotating BOPs, outweigh the potential casing wear. To accurately determine casing wear, all rotating ope

Download Presentation

Casing-Wear-and-Stiff-String-Modeling-Sensitivity-Analysis PDF 1

An Image/Link below is provided (as is) to download presentation

Download Policy: Content on the Website is provided to you AS IS for your information and personal use and may not be sold / licensed / shared on other websites without getting consent from its author.

Content is provided to you AS IS for your information and personal use only.

Download presentation by click this link.

While downloading, if for some reason you are not able to download a presentation, the publisher may have deleted the file from their server.

During download, if you can't get a presentation, the file might be deleted by the publisher.

E N D

Presentation Transcript

More Related